FOIA – June 2023: FDA Found Seven ‘Objectionable Conditions’ at Pfizer’s Michigan COVID Vaccine Manufacturing Site: Notifies Pfizer.

Most of us assume that pharmaceutical plants produce medications in clean, contamination-free settings and follow clear protocols. That should be the norm. But the FDA issued a Form 483 to Pfizer’s Kalamazoo, Michigan, manufacturing plant on June 16, 2023, revealing seven alarming observations about the conditions there. The plant is “…one of the U.S. finishing plants manufacturing Pfizer and BioNTech’s COVID-19 vaccine.”

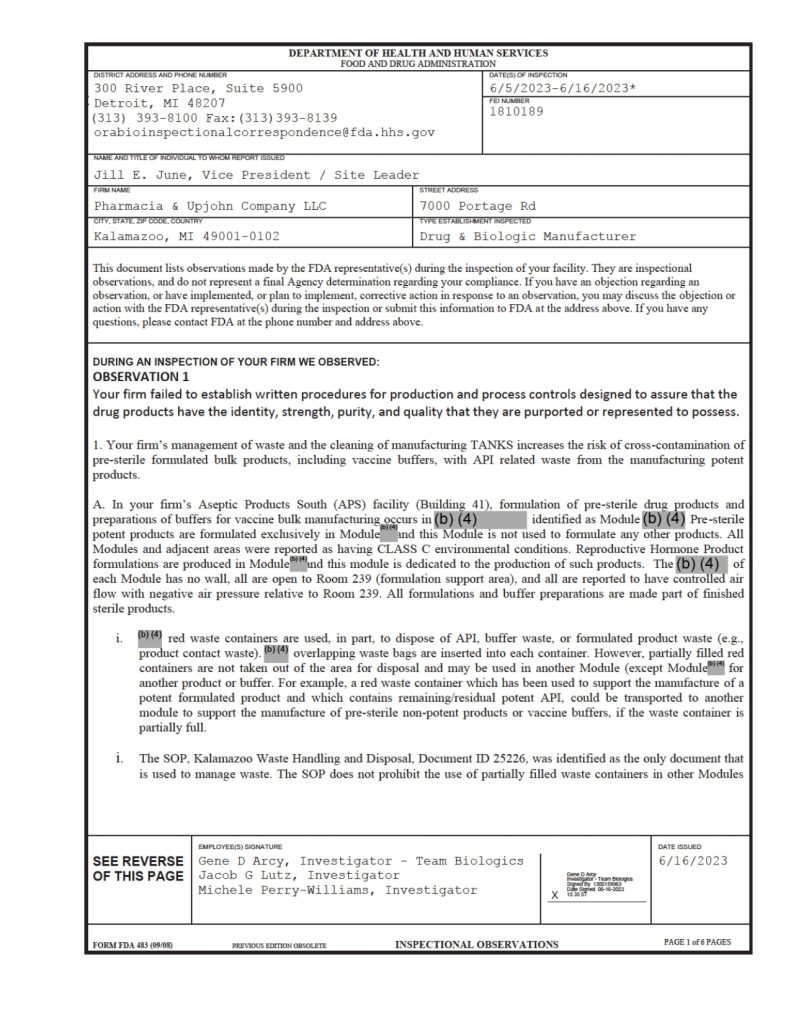

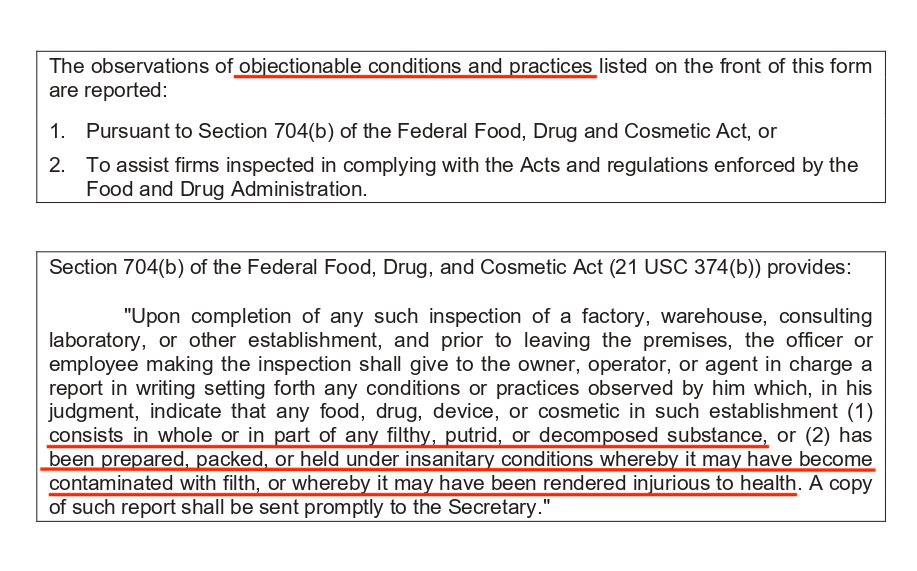

According to the FDA’s website, “FDA Form 483 notifies the company’s management of objectionable conditions.” [Italics mine.] The June 16, 2023, Form 483 issued to Pfizer’s Kalamazoo site stated:

This Form 483 notified Jill E. June, Kalamazoo Site Vice President/Leader of seven problems at her facility. The site:

- Failed to have proper written procedures;

- Did not have suitable construction for cleaning, maintenance, and operations;

- Lacked reviews to assure no errors occurred;

- Did not adequately validate the process to ensure products were free from living microorganisms that can cause disease;

- Used inappropriately designed and located equipment;

- Did not use a cleaning process that prevented contamination from dangerous organisms; and

- Failed to keep buildings used throughout the drug-making process “in a clean and sanitary condition.”

FDA investigators Jacob G. Lutz and Michele Perry-Williams noted in detail aspects of these seven unacceptable conditions. Their observations are below:

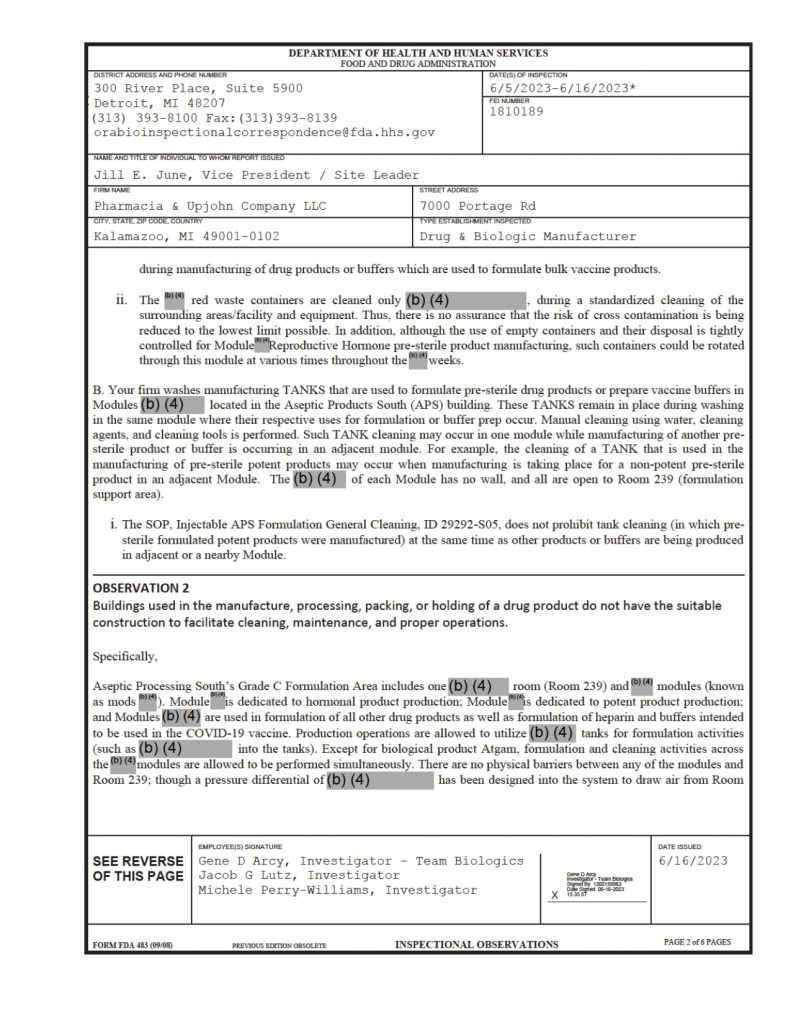

Observation 1: “Failed to establish written procedures for production and process controls designed to assure drug products have the identity, strength, purity, and quality that they are purported or represented to possess.” The investigators elaborated, “Your firm’s management of waste and cleaning of manufacturing TANKS increases the risk of cross-contamination of pre-sterile formulated bulk products, including vaccine buffers, with API [active pharmaceutical ingredients] related waste from the manufacturing potent products.” [Italics mine.]

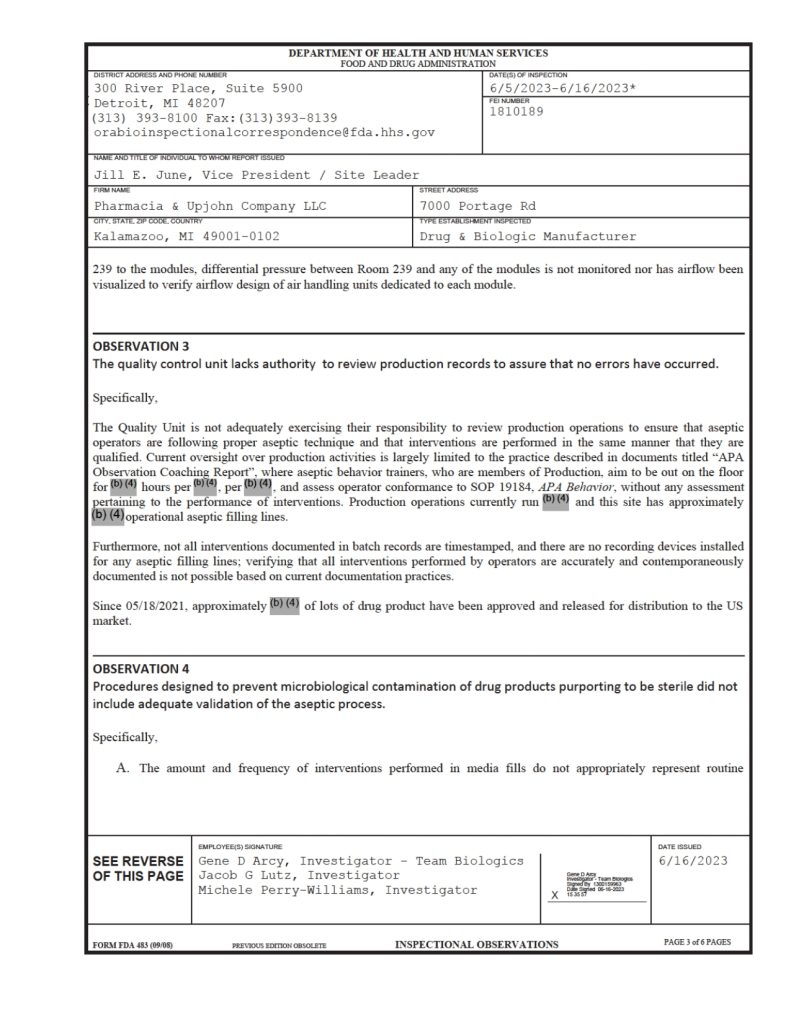

Observation 2: “Buildings used in the manufacture, processing, packing, or holding of a drug product do not have suitable construction to facilitate cleaning, maintenance, and proper operations.” Investigators’ notes went on: “No physical barriers between the Modules and the formulation support area,” as well as, “…differential pressure between [the formulation support area] and the modules is not monitored nor has airflow been visualized to verify airflow design of air handling units dedicated to each module.”

Observation 3: “The quality control unit lacks authority to review production records to assure that no errors have occurred. [Italics mine.] The investigators’ additional comments included: “The Quality Unit is not adequately exercising their responsibility to review production operations to ensure that aseptic operators are following proper aseptic technique and that interventions are performed in the same manner that they are qualified.” ‘Aseptic’ means free from pathogenic, or disease-causing, organisms. They continued: “Not all interventions documented in batch records are timestamped;” “There are no recording devices installed for any aseptic filling lines;” and “Verifying that all interventions performed by operators are accurately and contemporaneously documented is not possible based on current documentation practices.”

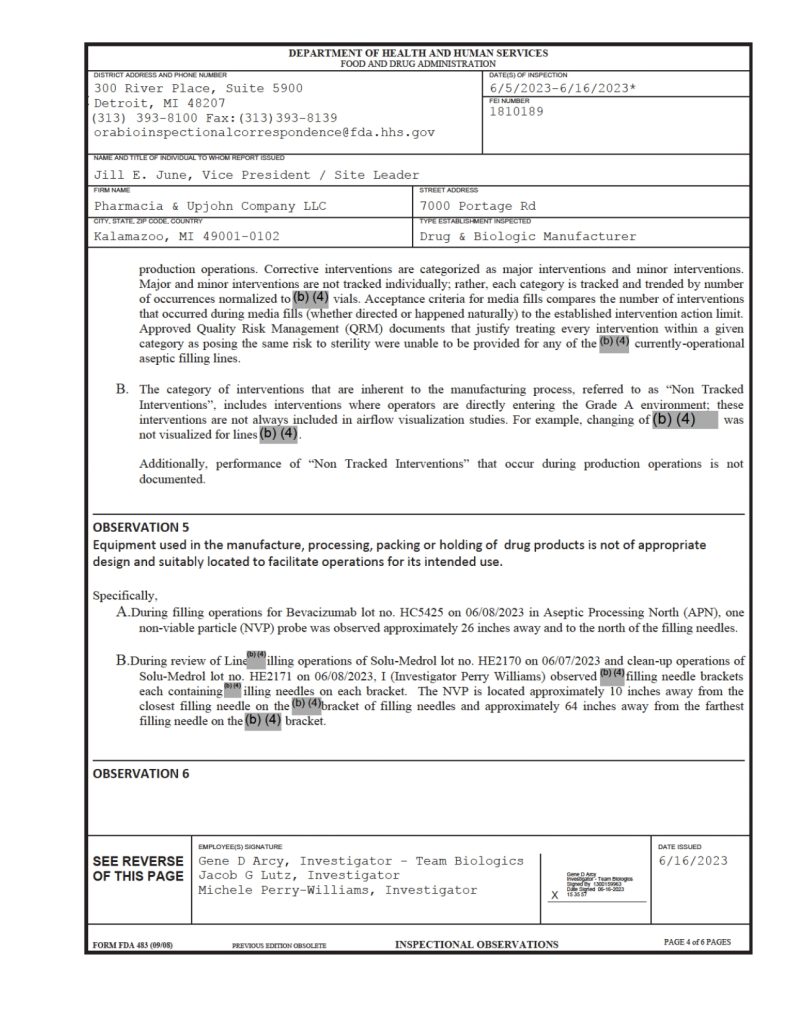

Observation 4: “Procedures designed to prevent microbiological contamination of drug products purporting to be sterile did not include adequate validation of aseptic process.” Investigators explained that the manufacturing process simulation known as ‘media fill,’ used to test whether procedures prevent product contamination, did “…not appropriately represent routine production operations.” Moreover, the site could not produce Quality Risk Management (QRM) documents which justified some currently used procedures. The Kalamazoo facility leadership did not insure employees followed Good Manufacturing Practices (GMP).

Observation 5: “Equipment used in the manufacture, processing, packing or holding of drug products in not of appropriate design and suitably located to facilitate operations for its intended use.” For example, non-viable particle (NVP) probes, which are critical for optimizing and validating that process simulation environments and processes are free from disease-causing pathogens, were not correctly located in relation to filling needles.

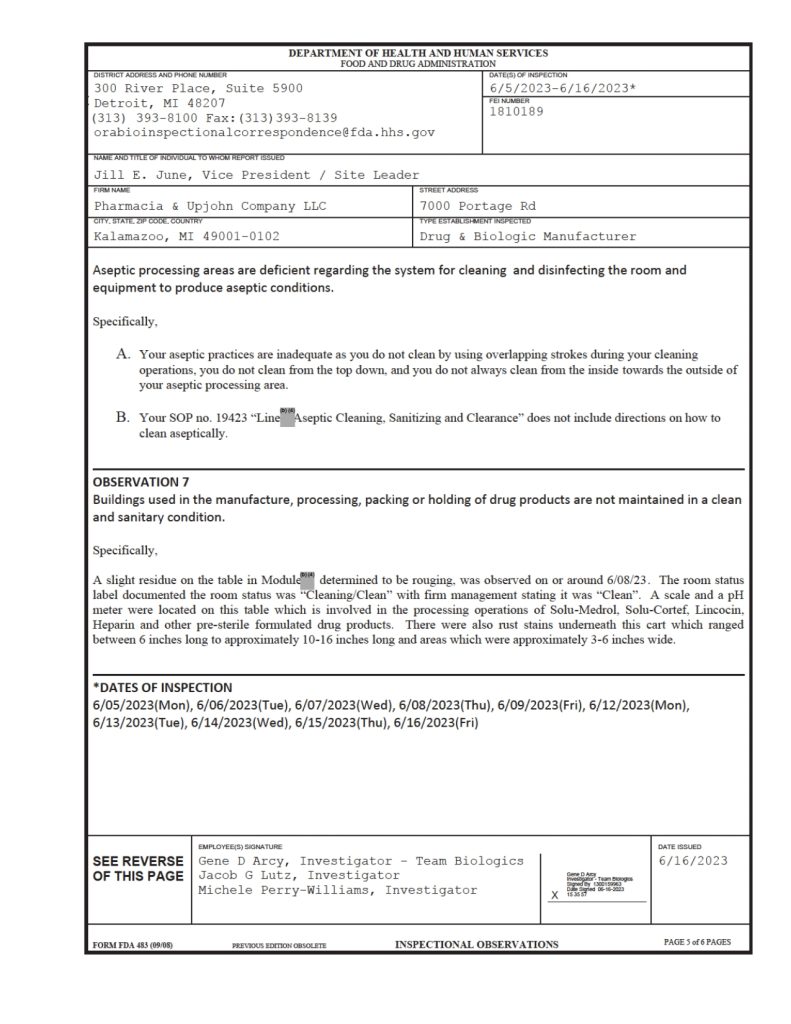

Observation 6: “Aseptic processing areas are deficient regarding the system for cleaning and disinfecting the room and equipment to produce aseptic conditions.” Investigators noted: “Your aseptic practices are inadequate as you do not clean by using overlapping strokes during your cleaning operations, you do not clean from the top down, and you do not always clean from the inside toward the outside of your processing area.” [Italics mine.] And, the site’s Standard Operating Procedure (SOP) on ‘Aseptic Cleaning, Sanitizing, and Clearance’ did not include directions for cleaning aseptically.

Observation 7: “Buildings used in the manufacture, processing, packing or holding of drug products are not maintained in a clean and sanitary condition.” The investigators saw residue on table, equipment improperly left on a table, and large (6″-16″ long and 3-6” wide) rust stains under a cart.

####

This is not the first time this facility has gotten into trouble with the FDA. A previous Kalamazoo site inspection resulting in a Form 483 occurred from June to July 2015. The 2015 inspection uncovered lapses which “included failure to investigate discrepancies and out-of-specifications results, inadequate annual product reviews, failure to follow written procedures for identifying, handling and storing containers, and inadequate documentation for cleaning procedures.” Moreover, “The Kalamazoo, Mich., plant received a 10-item Form 483 following a September 2010 inspection for many of the same issues.” Clearly, this 1,300-acre facility exhibits an on-going lack of adherence to GMP. In spite of all of the problems found in 2010 and 2015, Pfizer chose this dirty facility “to handle formulation and filling” for its mRNA COVID vaccine destined to be injected into 270,227,181 Americans by May 2023.

Below you will find the full Form 483 report for these violations which I obtained via FOIA.